Foam rubber insulation

Features and scope of application

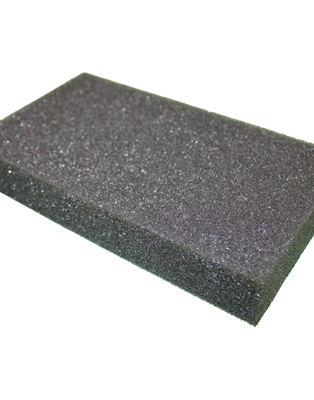

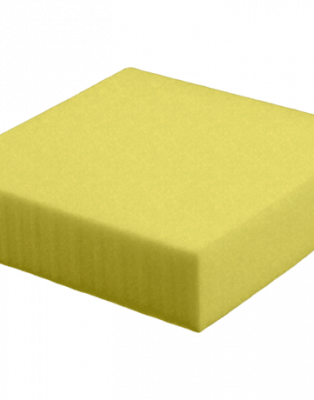

The main advantage of polyurethane foam is its low biological activity. It is not able to react with the environment, and the properties of the product directly depend on its quality and density. The soft porous material has a flexible structure, good elasticity, and low thermal conductivity. High-density polyurethane foam is low-permeable, which gives it noise, heat and waterproofing properties.

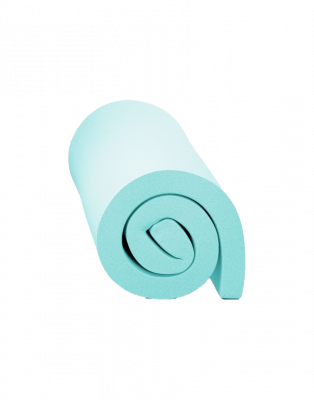

Such advantages of the product have given people the opportunity to use foam rubber as insulation. For this purpose, products with a density of 30-60 kg/m3 are used. This is a godsend for the construction industry, because such a combination of quality, functional characteristics, availability and ease of use is difficult to find among other finishing materials. The use of foam rubber as insulation for windows and for walls on the outside and inside, and roofs is equally effective.

Material advantages

- Polyurethane foam can be used on any surface: paper, brick, wood, metal, tile, concrete.

- Not afraid of bends and uneven bases.

- “Indifferent” to sudden changes in temperature and humidity.

- Once applied to a plane, the structure has no seams or joints, which prevents heat loss.

- Window and wall foam rubber can be applied already at the construction site during the construction of structures or during life, when the need has arisen to make repairs outside or inside the building.

- Does not allow frost to penetrate inside the building.

- Able to retain heat already accumulated in the house.

- Minimizes fuel consumption and energy consumption in winter (heating boilers) and summer (air conditioners and split systems).

External and internal use

Foam rubber is insulation for walls outside a building, the intended purpose of which is to prevent the penetration of cold, heat, and noise from the street into living spaces. Despite its airy structure, the material has a closed porous base. This allows it to withstand temperatures from +150°C to -150°C.

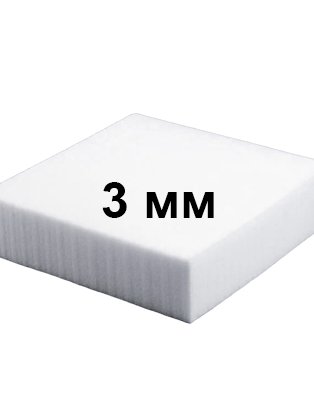

The only thing to avoid is heavy weight loads. But when used correctly for thermal insulation, they do not affect the raw materials. For sufficient insulation on the street side, you will need a material whose sheet width is 0.5 cm or more (based on the climate of the area). This will protect the building from the effects of frost, because PU foam allows cold to pass inside itself only to a distance of 0.2 cm.

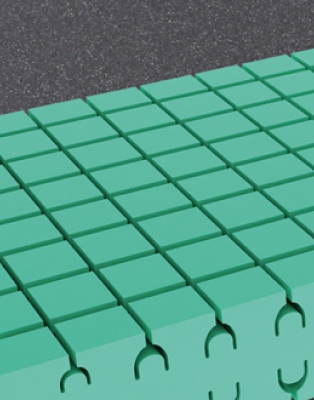

Foam rubber is used as insulation for windows due to its ability to allow air to pass through, but retain cold, noise and moisture. Buyers often choose the tape format of the product, which makes their work easier: just peel off the protective strip and glue the window around the perimeter. But there are other methods of application. Window foam rubber can be used during the installation of double-glazed windows or wooden frames, wrapping it along the entire length of the window block. Such protection will last for many years, protecting homeowners from the negative effects of the environment.